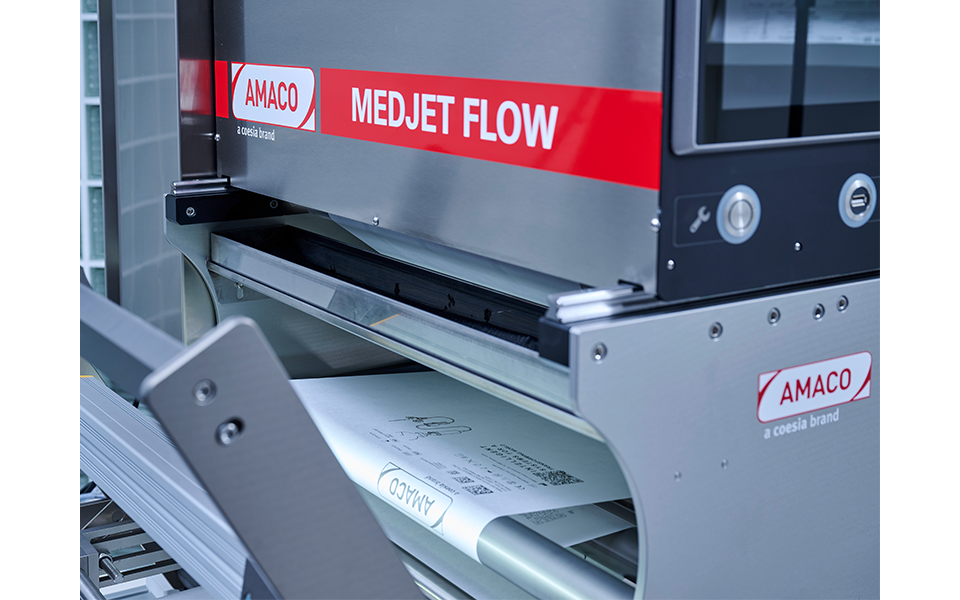

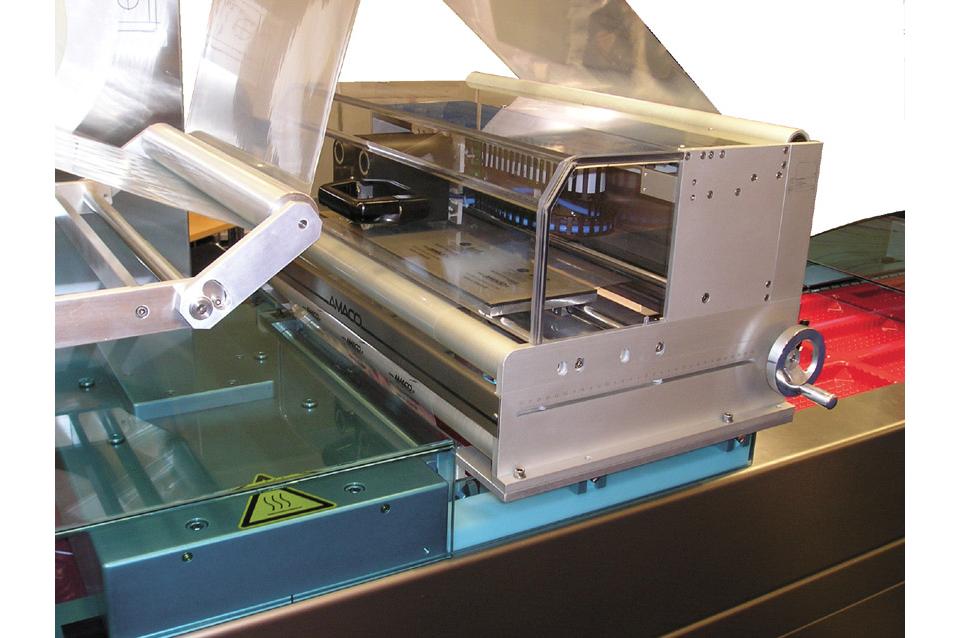

2024 – Launch of MEDJET PULSE

At COMPAMED 2024, AMACO unveiled the MEDJET PULSE—its most advanced single- or bi-color Piezo DOD inkjet printer to date. Built for high-resolution, stand-still printing at speeds of up to 500 mm/s on medical devices, it delivers UDI-compliant marking with low operating costs and built-in vision readiness. Designed for the demanding needs of modern medical production lines, the MEDJET PULSE combines speed, precision, and flexibility, ensuring consistent performance across a wide range of substrates.

This milestone reflects AMACO’s ongoing commitment to innovation, reliability, and excellence in medical device marking technology.